| Distance and Thickness Measurement | Measurement Principle | ||

|

LRS 3 |

||

|

Fig. 1: Basic Unit LRS 3 with sensor-head SP 40 |

|

|

|

The ultrasonic distance sensor LRS 3 comprises the ultrasonic sensor head and the basic unit with integrated display and function key. The new circuit technology and its programmable functions make the LRS 3 a perfect sensor for all kinds of non-tactile distance and thickness measurements. LRS 3 combines a large measuring range with high accuracy at the physical limits. Ranging is performed by emitting and detecting ultrasonic wave packages in air. The traveling time of the ultrasound from the sensor to the object and back is determined by using a fast responding foil transducer. The resolution of the sensor LRS 3 is better than 0,01 mm. The precision of the measurement is only depending on the homogeneity of the air. All kinds of objects made of concrete, stone, metal, plastic, wood, paper and glass can be measured. Even highly sound absorbing materials like foams, textiles and insulation mats can be detected not regarding their surface structure. The measurement is independent of the colour and other optical effects. A typical application is the on-line thickness measurement of products made of rubber, canvas, felt and concrete during the production process. |

||

|

The sensor-head has an integrated temperature sensor for measuring the mean air temperature. From this the velocity of the ultrasound is calculated. The measured distances are displayed on the LEDdisplay of the basic unit and are transmitted to a PC or other devices via a serial interface. By the function key the user can switch between relative and absolute measurement. The software LRS - TOOLS allows changing of the measurement parameters, such as upper and lower range limit, number of averaged cycles, analogue output gradient, sensor gain and relative / absolute measurement. LRS 3 can thus be adapted to the specific application. |

||

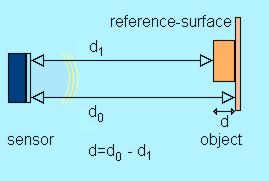

Fig. 2: Thickness measurement of an object lying on a

reference-surface d1 = distance of the object |

||

|

Fig. 3: Spread sheet of the software LRS - TOOLS |

||