|

Introduction

|

Application |

||

|

Viscoelastic Foam Testing |

||

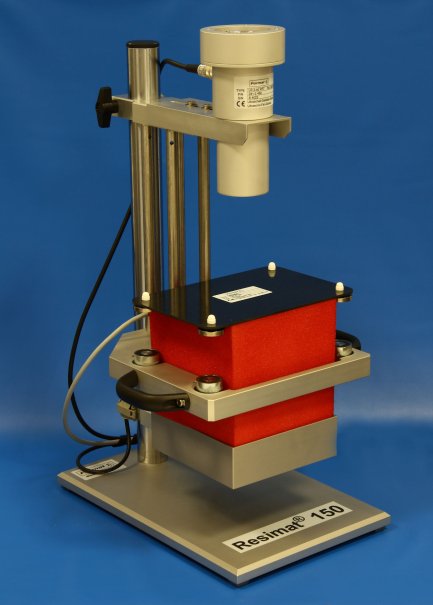

Fig. 1: Test device* Resimat for the measurement of the pressure relaxation and the recovery kinetics of viscoelastic foams. The mechanical set is designed for samples with a maximum edge length of 100mm. * patent 10252211.1-52 |

|

|

|

|

||

|

Viscoelastic foams show a characteristic creep behavior when loaded by an external force, i.e. the weight of a body. That gives them comfortable properties when being used in bedding and seating applications. Resimat (Fig.1) is a device especially designed for testing the pressure relaxation and the dimensional recovery properties of viscoelastic foams. |

||

|

Resimat can be used for the development as well as for quality assurance testing of viscoelastic foams. A test sample of standard dimensions (100x100x50mm³) is compressed vertically by means of a pressure plate onto an adjustable reference surface. At a certain compression two clamps fix the pressure plate and keep the strain for a pre-selected hold time. The Windows based software RESIMAT supports this procedure. While being compressed a force gauge measures the restoring force of the foam sample. Due to its viscous properties the force gradually decreases with time revealing the comfort parameters of the foam. The ratio of the primary and the final force is evaluated and displayed by the software RESIMAT. After the hold time the clamps are opened and the sample recovers from the deformation gradually regaining its original shape. An ultrasonic sensor positioned right above the pressure plate continuously records the kinetics of the sample surface. The thickness vs. time curve (Fig.2) shows the recovery process giving further insight into the dynamical features of the foam. |

||

|

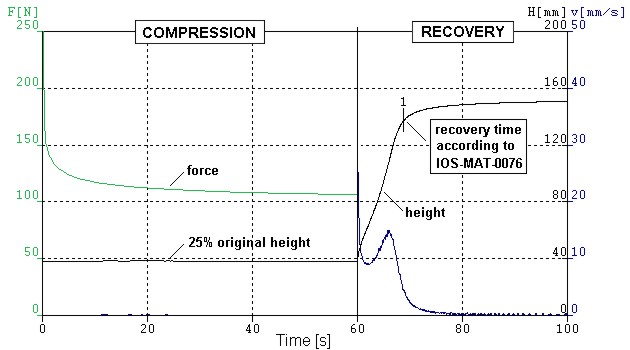

The distance of the reference surface and the primary sample thickness are measured in a zero measurement. Both data determine the sample strain. The hold time and the recovery duration are free selectable parameters. After compression and subsequent recovery the time dependant data is displayed graphically. The viscoelastic appearance and other test parameters evaluated from the curves are listed in a parameter list together with the input data. The viscoelastic appearance is an integral of the recovery curve showing how long a foam deformation remains visible. |

||

Fig. 2: Graphical display of the restoring force (left), showing relaxation, and the thickness of a recovering sample (right), re-gaining its original shape. Measurements with different viscoelastic foams are superimposed by the software RESIMAT. The “appearance” is the yellow area.

|

||

|

Resimat®

150 Recovery time measurement of viscoelastic foams according to IKEA® specification no. IOS-MAT-0076 |

||

|

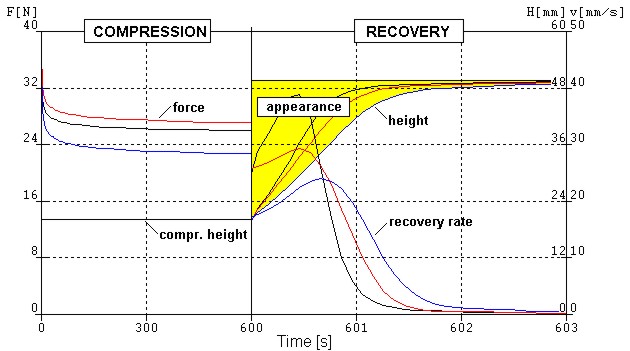

Fig. 3: Resimat 150 for recovery time measurement according to IKEA specification no. IOS-MAT-0076. The mechanical set is designed for viscoelastic foam cubes with an edge length of 150mm. |

||

|

The Resimat 150 (Fig.3) is designed to measure the recovery time according to the IKEA® specification no. IOS-MAT-0076. According to this, a viscoelastic foam sample with a dimension of 150x150x150mm³ is compressed to 25% of the original height. During the hold time the restoring force of the foam sample is measured continuously with a force gauge. After the hold time of 60 seconds the compression force is released and the sample recovers from its deformation gradually regaining its original shape. The time needed to recover to 90% of the original thickness is critical. It is evaluated from the height versus time curve, measured by the ultrasonic fan sensor PFT. Bejond that, the viscoelastic appearance, the final restoring force and other test parameters are calculated by the software RESIMAT. |

||

|

Fig. 4: Height (thickness) and force versus time curve of a viscoelastic foam cube with an edge length of 150mm, measured with Resimat 150. The time needed to recover to 90% of the original thickness is evaluated by the software RESIMAT.

|

||