Foam Qualification System FOAMAT® 285

Measuring Physical Parameters During Foam Formation

Measurement of:

Testing according to:

* Patent Nos. 3621819, 19730891 and 10044952

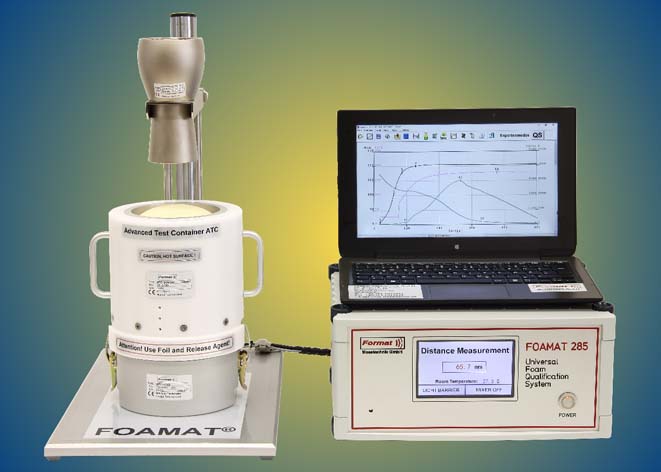

Figure 1: The Universal Foam Qualification System FOAMAT 285 is based on innovative technology for precision testing of all kinds of plastic foams. The ultrasonic fan-sensor LR 4 provides high data repeatability under all testing conditions. The enhanced technology of the Advanced Test Container ATC shows detailed cell formation data by a high resolution pressure sensor. The FOAM V4.0 software has new features, including density and specific volume curves.

Formation Parameters

The quality of polyurethane (PU), polyisocyanurate (PIR), phenolic and epoxy foams depends on the conditions during their formation. Therefore, it is sensible to record the formation parameters and to check representative samples regularly. Consistent product quality is ensured by measuring the formation parameters during the foaming process. The measured curves are compared to specified standards in the form of master curves. Many automotive systems suppliers apply this method to vehicle-interior parts and modules. The furniture industry, along with the construction and equipment insulation industry, also measure formation parameters for quality assurance purpose. When foam parts with special properties are being developed, measuring the foam formation parameters gives an insight into how the reaction is proceeding and how foam formation can be affected by additives, blowing agents, stabilizers, and the mixing ratio. By offering different types of test containers, the Foam Qualification System FOAMAT combines versatility and high measuring accuracy.

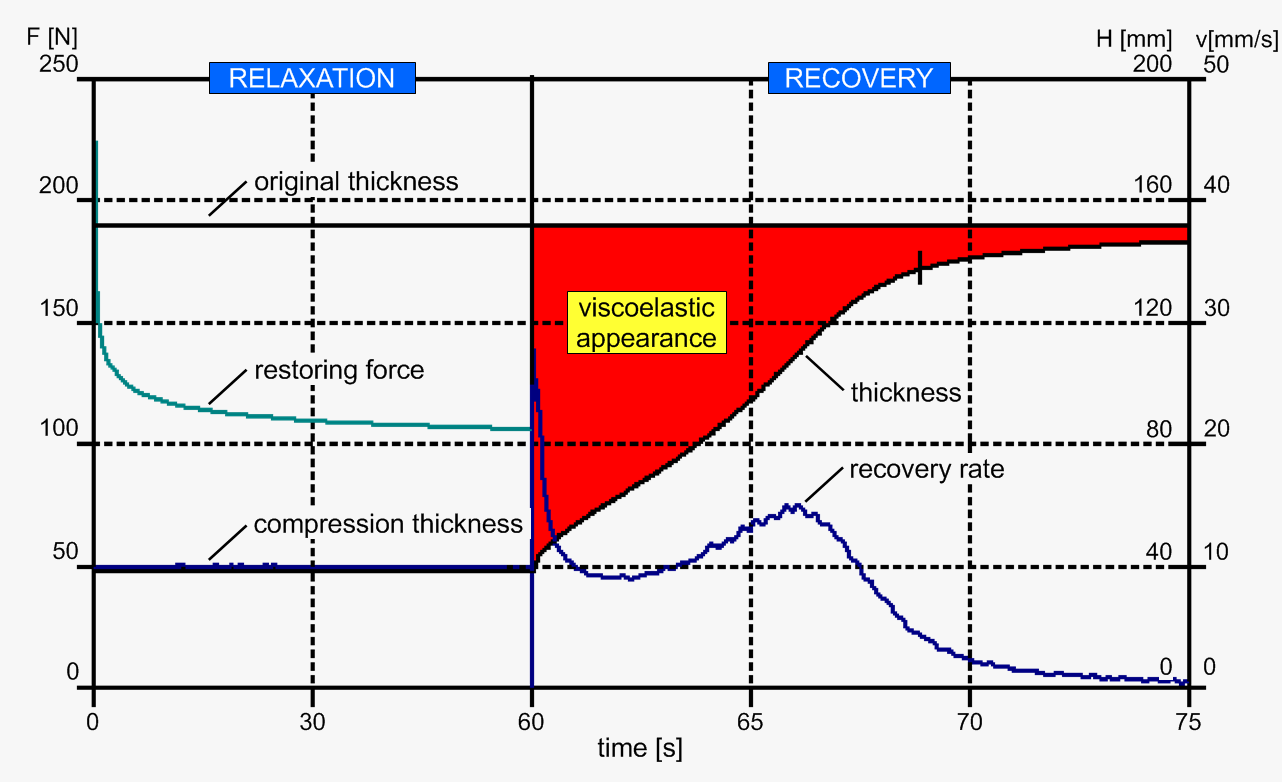

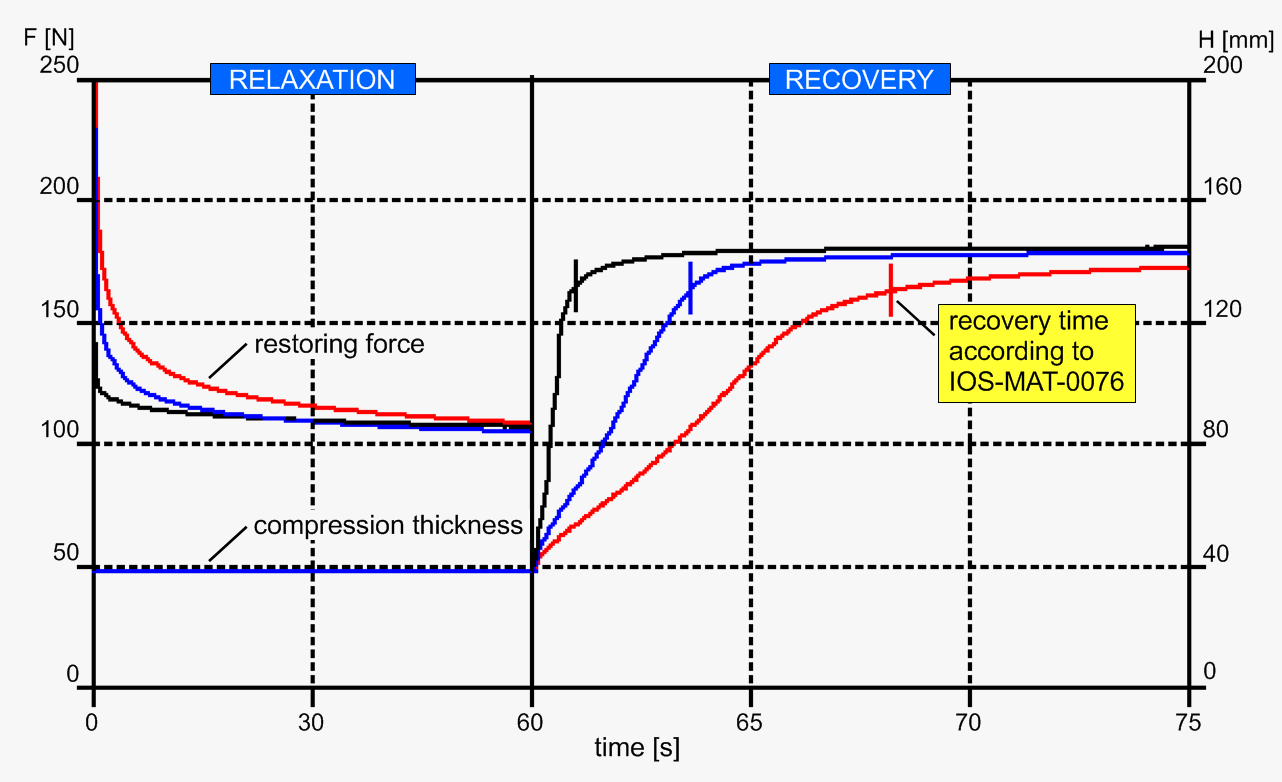

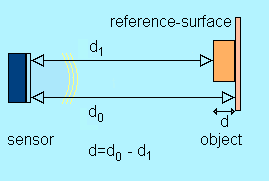

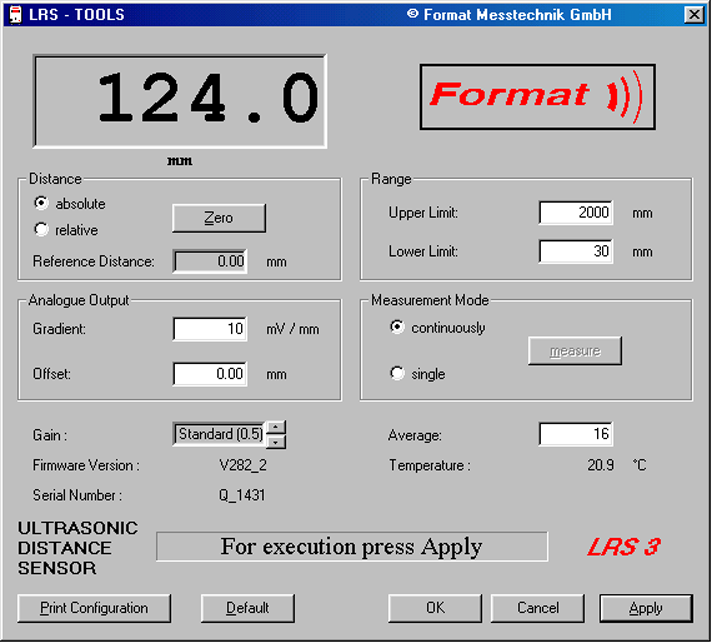

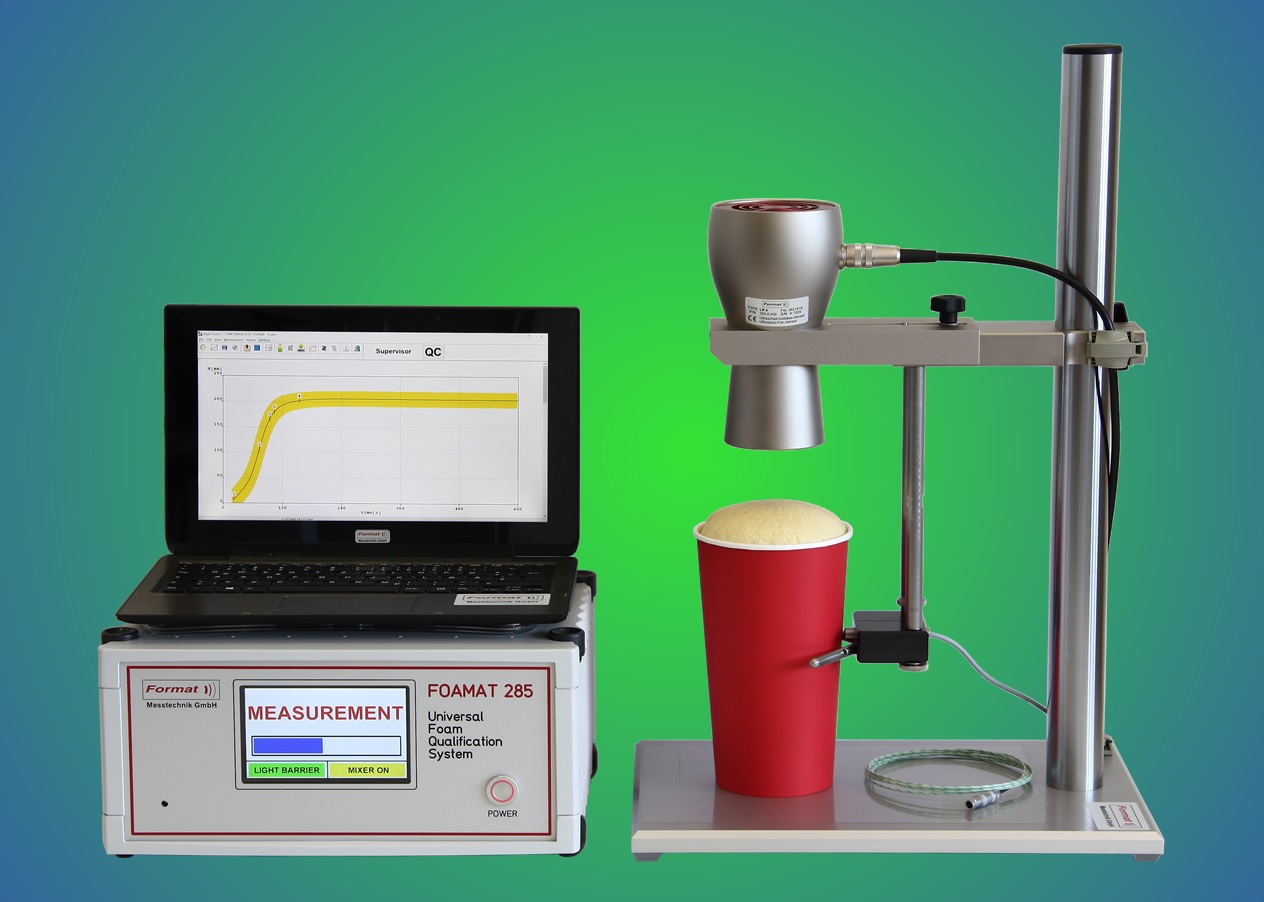

Rise Profile

The classic method of characterizing foams is to measure the rise height or rise profile. The expansion of a foam sample can be measured in a cup, a box, or a cylinder. The critical start time is evaluated from the rise rate. It indicates the start of the reaction between the reactive components after mixing. The rise time is another fundamental foam parameter. It is defined as the time between the start of mixing and the maximum expansion of the foam. The patented ultrasonic fan sensor LR4 of the FOAMAT system is especially designed for measuring the distance to the foam bun with high accuracy. It features an integrated fan for air homogenization, an ultrasonic sound transducer, and a temperature. All types of foams can be measured, including flexible molded and slabstock foams, semi-rigid foams, and rigid foams with strong heat release. The expansion containers can be heated to repeatable starting conditions as well as to reach the required reaction temperature. In quality assurance testing, the rise profile, which is the fingerprint of the foam, is compared to given master curves. A master curve is a tolerance band showing the margins of a “good” foam sample. While rise height measurement still continues to be the standard method of foam testing, new sensors of FOAMAT are available, revealing more details of the foam formation process.

Figure 2: The FOAMAT 285 base system comprises the ultrasonic fan sensor LR4 for rise height measurement, the temperature probe for core temperature measurement, the mechanical set, the controller unit, including the mixer control, and ther PC software FOAM.

Reaction Temperature

The compound formation and the cross-linking reaction cause an exothermal temperature increase in the foam sample. Thin thermocouples are ideal for measuring the temperature inside the foam as they have a low heat capacity and are easy to apply. They hardly interfere with the foam formation and can be used repeatedly.

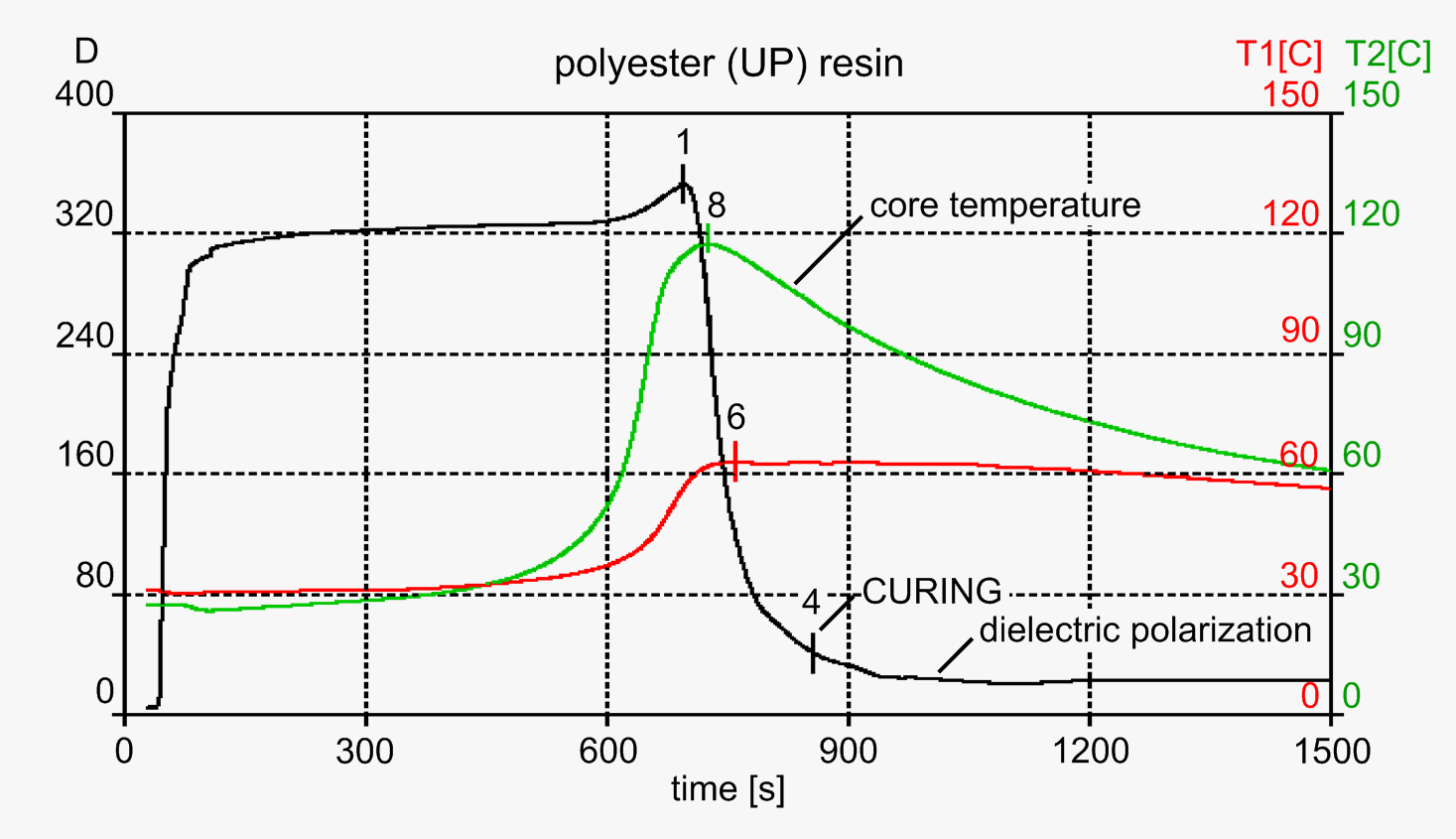

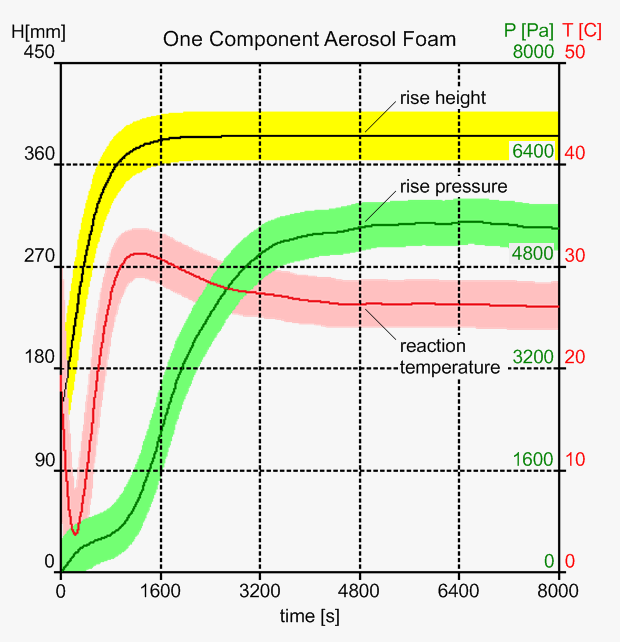

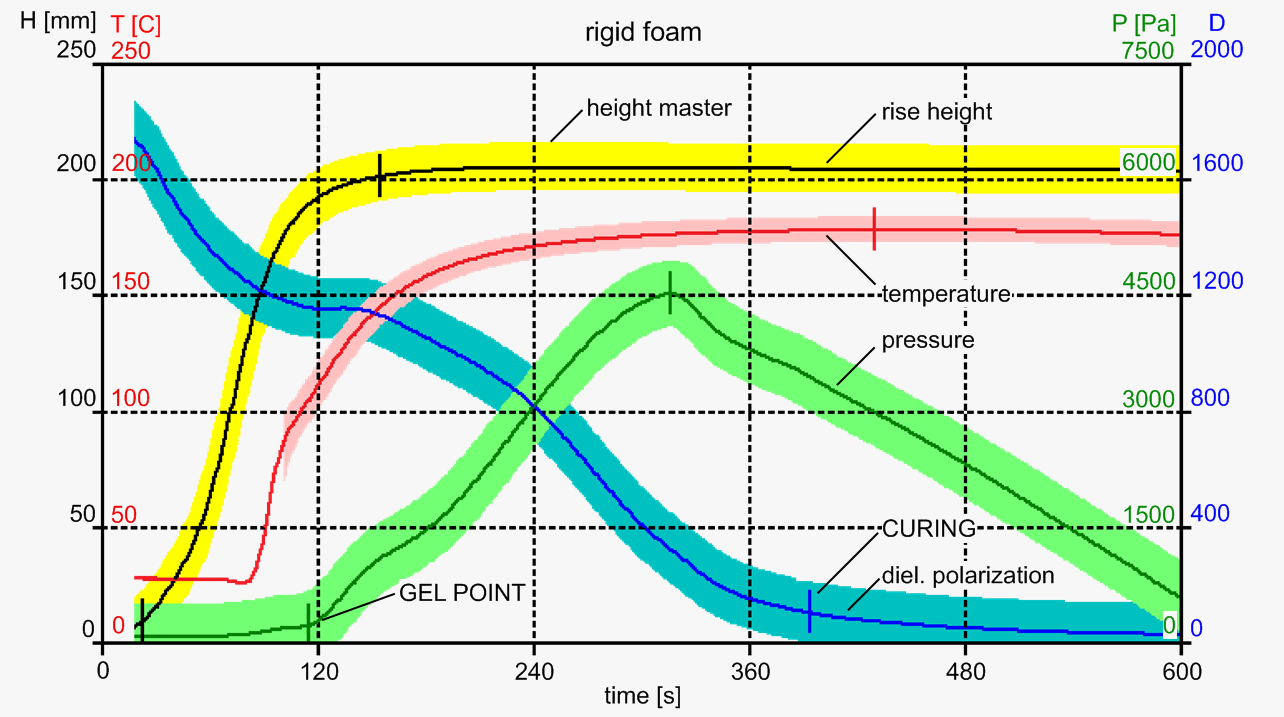

Figure 3: The curves show the reaction of a rigid foam measured by FOAMAT with FPM/CMD 150. Rise height (H), reaction temperature (T), rise pressure (P), and dielectric polarization (D) are recorded simultaneously by the software FOAM. The colored areas are master curves for QC.

Rise Pressure

Pressure builds up in the foam after the components have set. Stable cell walls are formed which hinder further foam expansion. The remaining blowing agents are trapped and heated. The increasing gas pressure causes stress within the foam. High pressure forces are generated by rigid foams in the production of wall elements and insulation panels. They are stressed at right angles to the direction of foam flow. In cylindrical test containers the stress at the bottom of a rigid foam sample can reach high values. The resulting load is named the "rise pressure" as it depends on the total rise height. The rise pressure is measured with the patented FPM (Foam Pressure Measurement) device, which is available with cylinder diameters of 70, 100 and 150mm. The FPM replaces normal test cups and boxes.

Whereas the rise curve reflects the blowing agent generation, the rise pressure mirrors the cell properties, which are affected by the polymerization reaction. Pressure measurement can yield valuable information about the effects of catalysts on gelling. Furthermore the rise pressure determines the blow off point of flexible foams and it can distinguish between open and closed cell formation. The pressure curve reveals the objective gel point. For production purposes, the pressure decay indicates the demolding time. Since the foam can expand freely to the top while the pressure is being measured, FOAMAT is able to measure the rise profile simultaneously. FPM devices are available with different cardboard cylinder diameters. For high density foams or low extrusion rates the FPM 70 is recommended. Its expansion volume is confined by cardboard tubes of 70mm diameter. For low density foams and big foam samples the FPM 150 is preferred. The FPM 2 with 100mm cylinder diameter has all-round features and can be used for many types of foam.

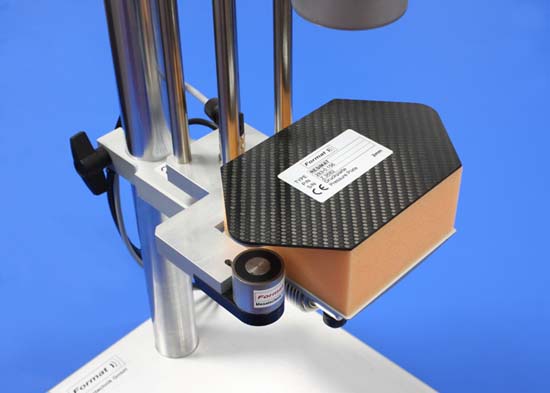

Figure 4: The CMD (Curing Monitor Device) sensor is mounted on top of the FPM 150 pressure plate (left), enabling the simultaneous measurement of the dielectric polarization and the rise pressure. The cardboard cylinder (right) with the cured foam sample can be removed from the FPM 150 device.

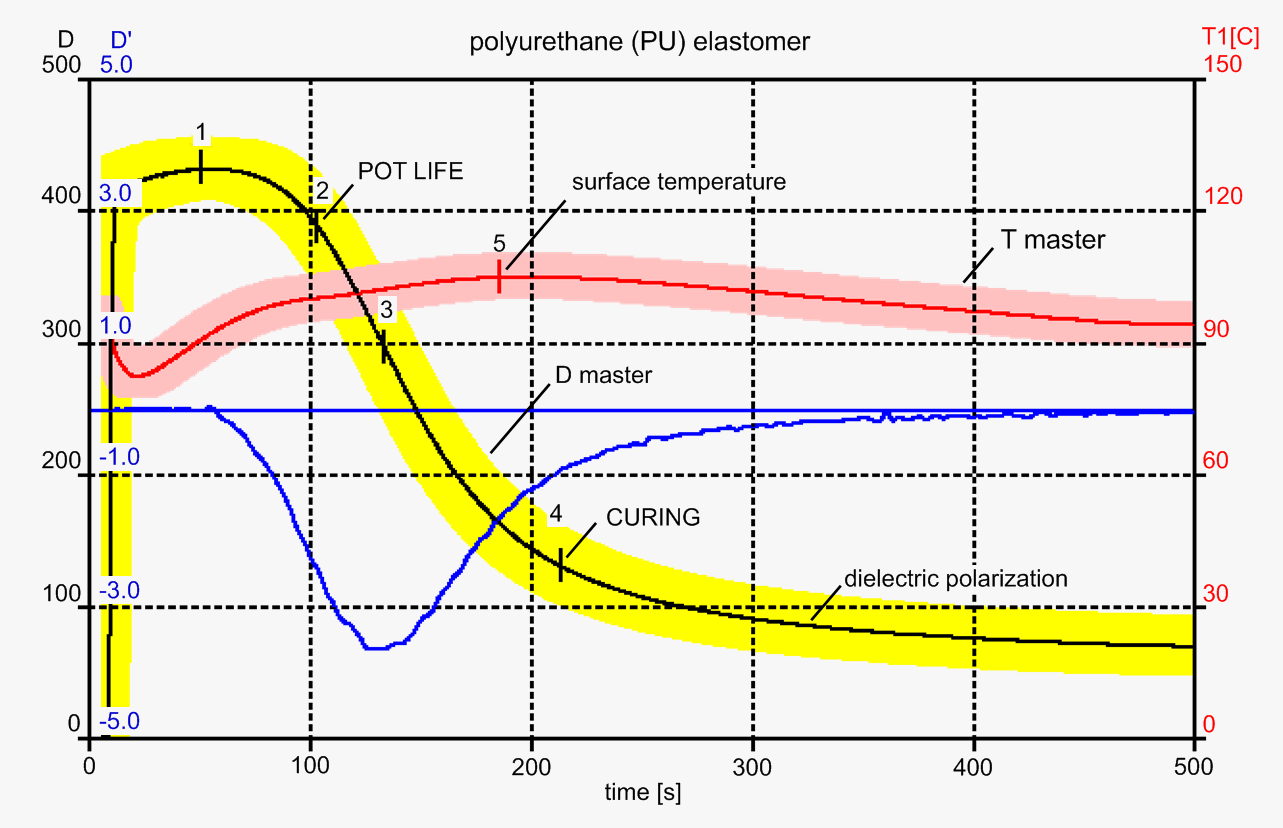

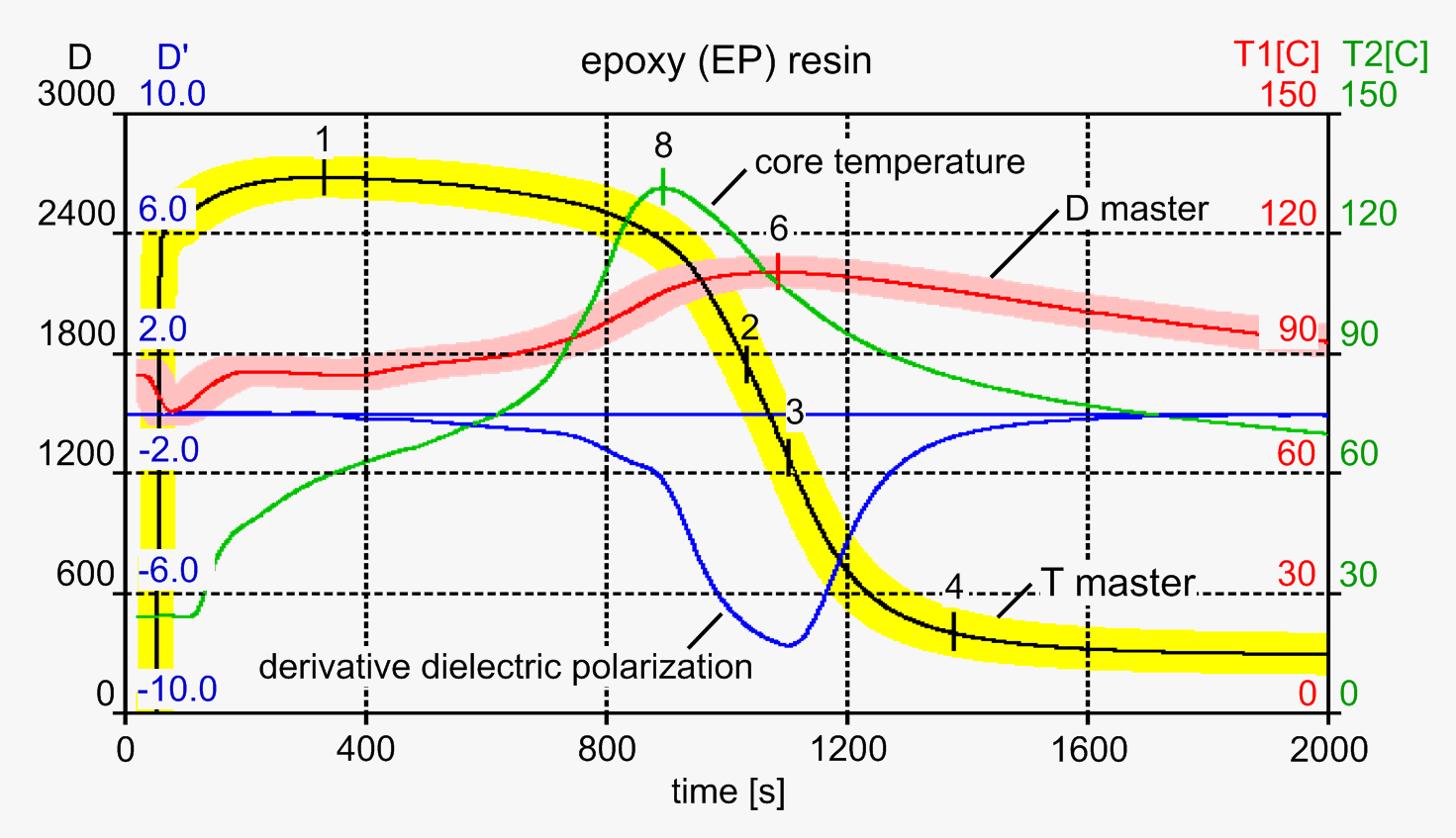

Dielectric Polarization

The dielectric polarization is a measurement parameter that gives insight into the electrochemical processes occurring during foam formation. Dielectric polarization is essentially caused by chain-like molecules with a large dipole moment due to their polar ends (OH, NCO groups for PU and PIR foams). Chain formation precedes the cross-linking reaction that ultimately suppresses all dipole mobility by curing. The dielectric polarization sensor CMD (Curing Monitor Device) is located on the pressure plate of the FPM. Due to the rise pressure, the foam is pressed onto the surface of the CMD. The dielectric polarization shows the formation of intermediates like amine and the final curing of the foam by decreasing to a low and constant signal after the chemical reaction has been completed. CMD is provided in combination with the pressure measurement device FPM. In order to simulate the production conditions in a mold, the CMD sensor can be heated with an electrical closed loop control.

Loss of Weight

In order to obtain reproducible measurement data, the reaction components must be weighed exactly. Despite the utmost care on behalf of the user, remnants adhering to the mixer head and remaining in the mixing cup may lead to uncertainties in the tested foam mass. The integration of a laboratory balance into the FOAMAT system automatically records the mass of each component in the batch documentation. Additionally, the loss of weight due to the release of blowing agents and volatile components during foaming process, as well as due to the buoyancy can be recorded continuously. Another advantage of the balance integration is the determination of the foam density from the mass of the finished foam sample and its final rise height.

Figure 5: The loss of weight is measured by a laboratory balance integrated into the FOAMAT system. The foam residue left in the mixing cup is used for this purpose.

Ambient conditions

The ambient data is measured by the meteorological station GFTB 200. The room temperature, the relative humidity and the air pressure is recorded automatically by the software FOAM. All meteorological data is stored with the other test data and displayed with the other measurement parameters.

Figure 6: The BFC 200 (Box Foam Container) is placed onto the base plate of the stand. A thermocouple is inserted into the foam using a special positioning holder. The ambient data is measured by the meteorological station GFTB 200.

Production Simulation

Disposable cups, boxes and cardboard cylinders are commonly used to measure the physical generation parameters of reactive foam formulations. These are typically non-temperature controlled test containers. In real production, however, molds and other foam surfaces are precisely thermostated. Undefined temperatures spoil the correlation between laboratory investigation and the production situation. This is critical especially for PIR and phenolic foams which only cure at elevated temperatures. The Advanced Test Container ATC and the larger version ATC XL overcome this problem by two temperature controlled closed loops for heating the bottom plate and the semi-cylindrical side walls. For measuring the foam formation parameters they comprise both, a Foam Pressure Measurement (FPM) and a Curing Monitor Device (CMD). Additionally the core temperature is measured with a thermocouple being inserted through the ATC wall. The ATC is re-usable and replaces consumables like cups, cardboard cylinders, and paper boxes.

Figure 7: Size comparison of two FOAMAT test containers: The FPM 70 (left) is designed for rise height and pressure measurement of high density foam samples. The picture shows a sealing foam in a 70mm cardboard cylinder. The Advanced Test Container ATC (right) is heatable from the bottom to the top and has semi-cylindrical side walls. The lower part contains a FPM/CMD 150 device for pressure and polarization measurement. The insulated upper part can be lifted to ease the ejection of the cured foam sample.

Reliable Test Results

Due to consistent temperatures, the measurement results of ATC are much more reproducible than those measured in non-thermostated test containers. The decrease of the dielectric polarization reveals information about the curing process. As expected, curing goes faster at higher temperatures and more foam volume is generated. The pressure data is more consistent when measured with ATC.

Figure 8: The Advanced Test Container ATC XL (center) has four times the test volume of the standard ATC (right). Each of them comprises an upper and a lower part, which are clamped by spring locks. The foam sample (left) can easily be removed from the upper part.

Easy Handling

Upon test completion, the ATC spring locks are released. The upper part of the ATC can be lifted and the foam sample can be removed easily from the device.

In combination with the established Foam Qualification System FOAMAT, the ATC is a versatile accessory for measuring foam parameters of all types of formulations under selectable temperature conditions. The pressure and the dielectric polarization data provide valuable information how additives influence the gelling and curing of the foam. Featuring consistent elevated temperatures, the ATC opens a new dimension in QC and development of PU, PIR, EPOXY and phenolic foam formulations.

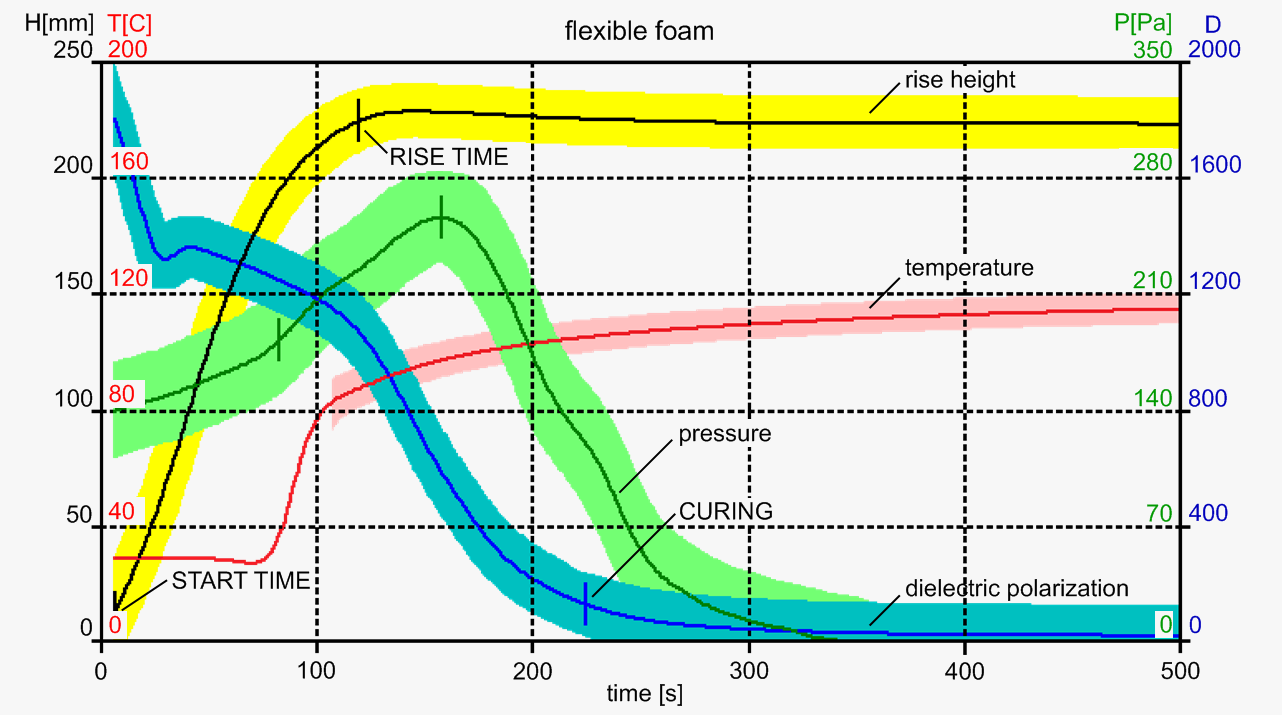

Figure 9: Rise profile (H), temperature (T), rise pressure (P), and dielectric polarization (D) curves of a flexible polyurethane (PU) foam. The start time and rise time are evaluated from the rise height data. The curing time is determined from decrease of the dielectric polarization.

Order No. 285256